Since the company was founded in 1970, UNTHA has been fulfilling its promise to be "The reliable brand", meaning that we do everything we can to be more reliable than other providers. This applies to all UNTHA products and services. For our customers, this means that choosing an UNTHA system was the best decision they could make.

Wood as production waste accumulates in numerous companies, from carpentry businesses to the packaging industry. Through shredding, a secondary fuel can be generated for numerous applications. Regardless of how you are planning to use the wood chips, we will configure the residual timber shredder exactly according to your needs.

Metal shredding is a necessary step in the recycling process, independent of whether your scrap metal comes from the metal-processing industry, the automotive industry, the electrical industry or the waste industry. Whatever your needs, we have the right shredding system for your recyclable materials!

Commercial and industrial waste is collected separately according to the respective components before being processed and reintroduced into the raw material cycle (recycling), or recovered for thermal recycling or for energetic utilisation (substitute fuels). UNTHA provides particularly efficient and flexible shredding machines for the 1-phase or 2-phase processing of commercial and industrial waste.

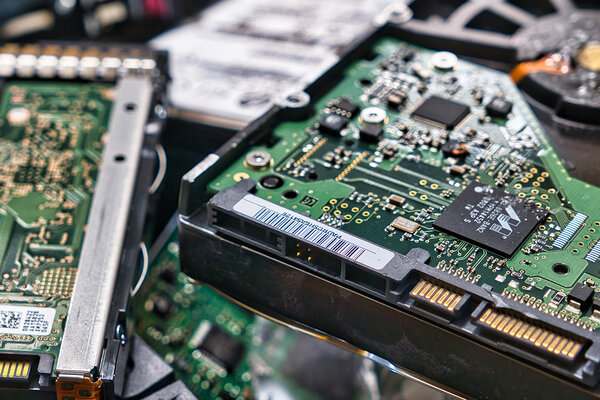

Due to advancements in digitalisation, electronic data backups on hard drives and digital storage media are becoming increasingly popular. Simply erasing hard drives prior to disposal is no longer an option, as the information can easily be retrieved by third parties. Only the mechanical destruction of hard drives can guarantee security to 100%. We provide reliable solutions for the shredding of hard drives in compliance with the DIN 66399-2 safety standard.

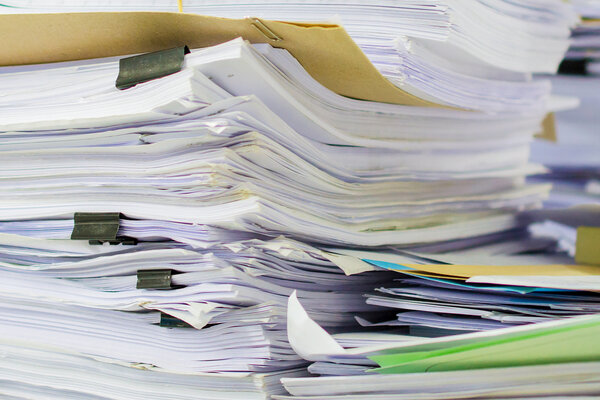

The reliable destruction of information set down on paper (files, documents etc.) ensures that your sensitive and confidential data cannot get into the hands of third parties - irrelevant of whether this concerns your own internal data or that of your customers. With the aid of our tried and tested four-shaft confidential waste shredder. we guarantee the secure and uncompromising destruction of your data pursuant to the most recent DIN 66399 standard!

Year after year, the volume of waste from used tyres and other rubber keeps growing. Our shredding systems produce tyre chips or granulates according to your exact specifications, even from the toughest rubber and used tyre materials. Whether the granulate is intended for pyrolysis, hydrolysis or incineration, we can tailor it to your specific needs.

Our shredders are perfectly suited for chemically aggressive material in your hospital waste, as well as other hazardous waste. After the shredding process, the material can be optimally utilised thermally, or disposed of together with normal waste subsequent to being sterilised. The shredding is so efficient that the granulate does not give any indications of the source material.

Pallets and wood packaging are an essential component in the transportation and storage of stackable goods as well as heavy and valuable objects. Our pallet shredders, which are highly resistant to extraneous materials, have been especially designed for shredding these products.

In 2019, almost 40 million tonnes of household waste were accumulated in Germany alone. This residential waste is collected and amongst other things sent for mechanical-biological waste treatment at the appropriate plants. Our reliable and particularly efficient waste shredders are perfect for the treatment of very different material streams.

Approximately 30 kg bulky waste is produced per capita every year in Germany. Bulky waste is waste which cannot be disposed of as normal residual waste due to its size and condition. This figure is relatively low in comparison to the quantity of normal household waste produced, but its condition makes bulky waste far more difficult to deal with. For this purpose, we offer you our powerful single-shaft and 2-shaft shredders.

Pulper ropes represent a special kind of waste. They accumulate during the production of paper - or, more precisely, during the recycling of waste paper. Half of these so-called rejects generally consist of metal, which is why their processing is particularly arduous and challenging. With our XR shredders, we offer you a tried and tested, single-stage shredding solution.

Waste wood is a valuable resource which accumulates in large quantities, and - depending on its quality - can be recycled to recover materials or produce energy. Rising disposal costs and growing environmental awareness mean that waste wood recycling is consistently increasing in significance. Our shredders are optimally equipped for the purpose.

Due to its versatility in use, plastic is primarily utilised in industrial mass production. The generated plastic waste can be recycled through shredding, washing and subsequent generation of granulate to produce a recyclable material (for the recovery of materials or energetic utilisation). The UNTHA plastic shredders have been developed specifically for this treatment process.

You can shred waste paper, cardboard and also entire paper rolls using our shredders, and thus recycle them at a profit. We will optimally configure our shredding solutions to meet your needs, and thus guarantee a consistently perfect result.

Electronic scrap comprises old electrical and electronic devices, as well as components of these which can no longer be used. Electronic scrap is divided into various categories depending on its size and type of use. These devices contain valuable raw materials such as iron, aluminium and copper, but also precious metals such as gold and silver.

Organic waste comprises all biological waste accumulated in households, gardens or agricultural or commercial or industrial operations which can be decomposed by micro-organisms, soil organisms and enzymes. Our shredders process biological and biogenic waste to generate an optimal substrate for further utilisation in your biogas plant or in your disposal business.

Professional destruction and recycling of waste from manufacturing processes is carried out in the highly sensitive field of product destruction. It is immaterial whether this concerns counterfeit products, production parts, prototypes or pirate copies - the end result must be guaranteed in a completely traceable destruction process. With our shredding machines, we can provide a high level of competence in producing solutions for this special application case.

Due to their varying material structure, mattresses are difficult to shred and/or recycle. Which is why they are often simply thrown away rather than being put to any further profitable use. Our powerful shredding solutions are specifically designed for this challenging task.

Discover the world of reliable waste shredding machines

object: /Product/XR2000-3000_1

object: /Product/ZR2400 mobil-e_1

object: /Product/ZR2400_1

object: /Product/RS30-40 Recycling_1

object: /Product/RS50-60-100_1

object: /Product/RS150_1

object: /Product/LR520_1

object: /Product/LR630_1

object: /Product/LR700_1

object: /Product/LR1000-1400_1

object: /Product/RS30-40 Holz_1

object: /Product/PS1300_1

object: /Product/LRK700-1000-1400_1

object: /Product/Product - Gebrauchtmaschine

Here you can read what our customers have to say about their successful experience of working with UNTHA and about our outstanding products.

object: /News/2025/News - OWI

object: /News/2025/News - Employer Ranking 2025

object: /News/2025/News - Vertriebspartner Japan

object: /News/2025/News - 10 Jahre UNTHA DE

object: /News/2025/News - Power Core

object: /News/2025/News - Service

object: /News/2025/News - Messen Polen

object: /News/2025/News - Türkiye Donation

object: /News/2025/News - Sunnking

object: /News/2025/News - TIC

object: /News/2025/News - UNTHA Demo Tour

object: /News/2025/News - MIKI Recycling

object: /News/2025/News - LIGNA Rückblick

object: /News/2025/News - XR – one of the best (pre-)shredder

object: /News/2025/News - Secure Recycling

object: /News/2025/News - LIGNA 2025

object: /News/2025/News - MyUNTHA PR

object: /News/2025/News - UNTHA PS1300 – effizienter Paletten-Zerkleinerer

object: /News/2025/News - Royal Mint turn e-waste into gold

object: /News/2025/News - Boardtek transforms wood waste into energy with shredder investment

object: /News/2025/News - UNTHA transforms waste wood into biomass

object: /News/2025/News - Plastic recycling RDG

object: /News/2025/News - 10 new features of the advanced generation RS

object: /News/2025/News - UNTHA PS1300 – effizienter Paletten-Zerkleinerer

object: /Event/Messe - CDRA Conference

object: /Event/Messe - Green Tyre Summit

object: /Event/Messe - CemFuels Asia

object: /Event/Messe - Eurobois

object: /Event/Messe - Asia EnwastExpo

object: /Event/Messe - Automotive Meetings Queretaro

object: /Event/Messe - Plastics Recycling Conference

object: /Event/Messe - Residuos Expo

object: /Event/Messe - SOLIDS & RECYCLING-TECHNIK

object: /Event/Messe - HOLZ HANDWERK

object: /Event/Messe - ReMa

object: /Event/Messe - WasteExpo

object: /Event/Messe - IFAT

object: /Event/Messe - SRR